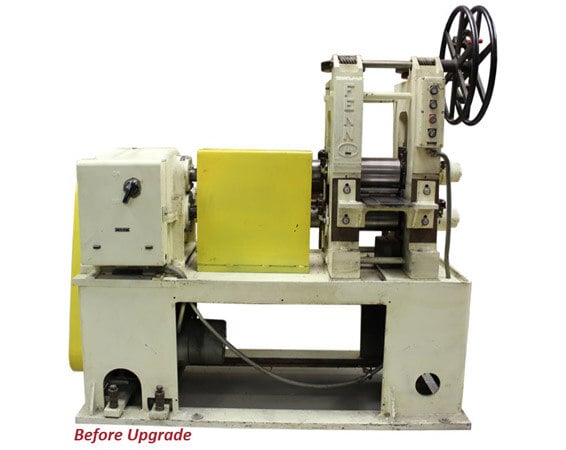

For more than a century, thousands of companies across the globe have trusted FENN equipment to achieve their metal forming requirements. However, over time, applications and production requirements can change, and machines may no longer prove useful in their original configuration. Rebuilds, Retrofits, and Upgrades can prove to be a favorable choice for customers unable to adequately use their existing metal forming machine. For a fraction of the cost of a new machine, FENN equipment owners can increase their machine’s capabilities and stay current with safety standards, all while improving accuracy and increasing repeatability.

Whether your equipment has worn out or your production requirements have changed, FENN’s expert staff is available to provide an upgrade solution to meet the needs of your unique application. As an important part of the total solutions package to our customers, FENN proudly provides upgrade and remanufacture services to all FENN and Torin brand metal forming machinery. With this service offering, FENN machinery owners can take advantage of the OEM’s knowledge of the equipment and expertise to mechanically and/or electrically rework aged machines and provide improved efficiency and quality, greater throughput, and increased safety. With FENN upgrade offerings you can add improved functionality to any of your aged FENN metal forming machinery, including Turks Heads, Rolling Mills, Swagers, Spring Coilers, Wire Flattening and Shaping equipment and Drawbenches.

Machine operators find that updated equipment helps to ensure reliable tolerances and part consistency, which allows manufacturers to avoid material rework and lost production time. Rebuilds, retrofits, and upgrades are available on all FENN products, including rolling mills, wire flattening and shaping equipment, and drawbenches.

Retrofits and Upgrades for Torin Spring Coilers

FENN is a long-standing and respected brand with a large installed base of older Torin model mechanical Spring Coilers. FENN offers both CNC control upgrades and mechanical retrofits for aging Torin Spring Coilers. The Torin mechanical retrofit program is designed to maximize the potential output of older model Torin Spring Coilers with the latest Torin CNC technology, all backed by our 1-year retrofit warranty! Retrofitted machines become simplified with fewer mechanical parts that need future replacement.

Mechanical Retrofits – The Torin mechanical retrofit program is designed to maximize the potential output of older model Torin spring coilers with the latest Torin CNC technology. With the elimination of clutches, brakes, and feed crank gears, retrofitted machines become simplified with fewer mechanical parts that need future replacement. The precise, variable speed servo control of the feed and camshaft independently enables greater flexibility when making complex springs. This also eliminates the need to change gears or adjust feed crank gears, clutches, and brakes and allows for camshaft reversals. Additionally, unlimited accurate feed length is provided by precise servo control. Experience expedited set-up time by adjusting the timing of the camshaft via offsets in the spring program rather than re-clocking the cams mechanically. Also save time and labor by using modern Torin programming. Maximize your machine’s potential with a rebuild!

Electrical Upgrades – FENN also offers CNC control upgrades for older Torin servo-controlled coilers. The control retrofit includes a complete replacement of the control system with the same state-of-the-art technology that is currently implemented on new spring coilers. With this package, you can eliminate the risk of relying on obsolete components, low production rates, and other issues such as poor-quality springs and worn mechanics. Additional benefits of updating your controls to modern systems include: greater efficiencies, easier for operators to learn and use, as well as increased productivity. Modernized platforms ensure your machine can be supported for years to come. When you increase the reliability of your machine, you minimize the risk of future downtime for repairs.

"We decided to have our worn-out W-125SA Torin mechanical coiler retrofitted to a 2-axis servo coiler because our production required more feed length than a standard mechanical offered. We have other FENN Torin coilers in our shop and are pleased with the support and customer service. The 2-axis retrofit has met our expectations regarding ease of setup since there was no learning curve for the setup and programming of the retrofit. We recommend the Torin retrofit program as an economical way of rebuilding used FENN-Torin coilers. It was the right choice for us. We have also purchased a rebuilt/retrofitted FENN Torin FZ-115 6-axis coiler." – John Bentz, James Spring & Wire Co.

"We decided to have our worn-out W-125SA Torin mechanical coiler retrofitted to a 2-axis servo coiler because our production required more feed length than a standard mechanical offered. We have other FENN Torin coilers in our shop and are pleased with the support and customer service. The 2-axis retrofit has met our expectations regarding ease of setup since there was no learning curve for the setup and programming of the retrofit. We recommend the Torin retrofit program as an economical way of rebuilding used FENN-Torin coilers. It was the right choice for us. We have also purchased a rebuilt/retrofitted FENN Torin FZ-115 6-axis coiler." – John Bentz, James Spring & Wire Co.

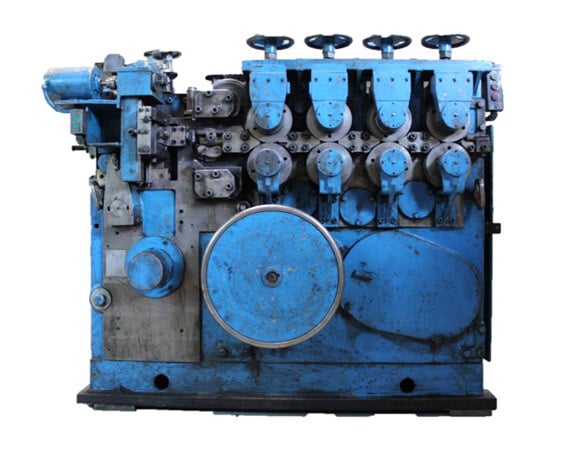

Swager Rebuilds

With rebuild service offerings, FENN machinery owners can take advantage of the OEM’s knowledge of the equipment and expertise to mechanically and electrically rework aged Swagers. The first step to rebuilding your Swager is to call FENN. After discussing the condition, age, wear and production goals of your machine, FENN’s experts will be able to make a recommendation for your rebuild. The next step is to ship your machine to FENN (located in East Berlin, CT) where our knowledgeable factory technicians will complete a full mechanical and electrical evaluation of your Swager. FENN will then provide you with a Comprehensive Swager Evaluation (CSE), which will outline customized recommendations based on your machine’s age, condition and intended application. An estimate of time, labor and materials required for the rebuild will all be included in your personalized CSE report. Upon review, you may choose to take back your Swager or proceed with the rebuild process. To learn more about FENN’s Swager rebuild program, contact us today!