MacBee Equipment

Various drawing equipment utilizing MacBee's simple and reliable mechanics

Product Lines

- Pointers

- Spoolers

- Spooler Payoff & Take-up Equipment

- Multi-pass Draw Machines

- Bull Blocks

- Dead Blocks

- Wire/Rod Payoffs

- De-Scaler/Wire & Rod Cleaners

Ancillary Options

- Accumulators

- Rotating Die Boxes

- Dead Block Take-ups

- Upenders

- Crimpers

- Packaging Turntables

- Rebuilds & Retrofits

- Spare Parts

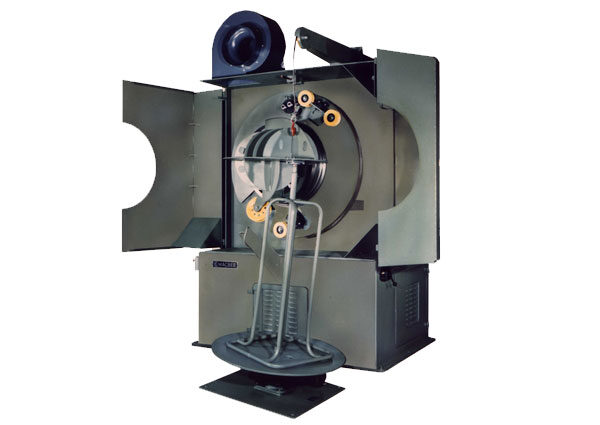

Bull Blocks

For wire or tube .010” – 2” diameter | Block sizes up to 96” diameter | Air or water-cooled blocks available

Means of drawing wire as a single unit. The wire is reduced in the die box and collected in the capstan as a loose coil, or it goes into another process from the capstan. It can be used as a single unit, or in tandem with other machines. Types of Bull Blocks include:

- Horizontal Bull Block used for single draw coil removal on block pins or in line with Spoolers or Dead Blocks

- Inverted Bull Block used for single bright basic draw coils onto the turntable. Inverted blocks can be above ground or with a pit for turntable (indexing turntables are available)

- Vertical Bull Block to be used with block strippers

- Barrel Pack Bull Block paying out the wire from a barrel

Inverted Bull Block above floor

Inverted Bull Block with Pit

Barrel Pack, Inverted Bull Block

Side Winder Bull Block

Vertical Stripper Bull Block

Dead Blocks

For wire or tube up to 7/16” | Block sizes up to 36” diameter

Dead Blocks are stationary horizontal shaft machines with curved arm types. They are utilized for drawing and/or coiling of wire, always as a finisher and normally in conjunction with a draw machine. Dead Blocks make it a non-stop operation when used in line with another draw machine or draw line. Types of Dead Blocks include:

- Free Standing Draw or coil

- Double Draft Infinite to 30% R/A between blocks.

- V-Groove Dead Block Take-up Ideal for annealing ovens and coating lines.

- Live Block Take-up Ideal for use with annealing ovens and coating lines

Freestanding Dead Block

Double Draft Dead Block

.jpg?width=600&height=425&name=Live-Blocks%20(1).jpg)

Live Block Take-up

V-Groove Dead Block Take-up

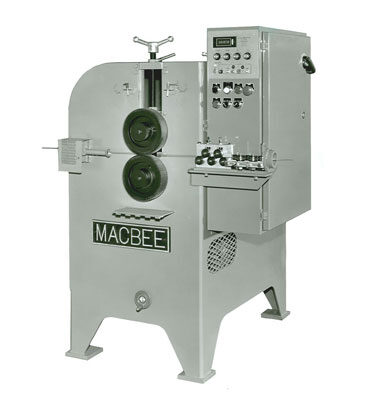

De-Scalers | Wire & Rod Cleaners

Speeds from 800 to 1750 FPM

To clean the OD of the wire, the De-Scaler takes the scaled material off the wire rod that has been heat treated and has a scale on it. Can be used offline or inline during the wire drawing process. Types of De-Scalers include:

- Brush System uses brushes to clean the scale off for any type of wire up to ½” diameter

- Breaking Roll System uses rolls to clean the scale off for any type of wire up to ¾” diameter

Six Breaking Roll Cleaner System

Six Brush Cleaner System

Multi-Pass Draw Machines

.006” – ½” diameter for tubing and wire | Speeds up to 3350 FPM

For all types of solid wire, specialty metal wire & various types of tubing

Unlimited number of passes and combination of motors and block sizes to suit your needs. Available with no cooling, air cooling, and air/water cooling for blocks and water-cooled dies suitable for dry powder and wet lube drawings. Types of Multi-Pass Draw Machines include:

- Dry Lube Drawing Ideal for sink drawing of tubing

- Wet Lube Drawing

Slip type

Non-slip type via dancer - X Series Modular construction

- Dancer Type Drawing Used primarily in multi-hole drawing. It can accommodate any R/A % between each block, makes up for any wear on the die, and still follows line speed. It is an ideal machine for running multiple ranges of finish sizes.

Dancer Type Drawing

Wet Lube Drawing

Dry Lube Drawing

X-Series

Roll Pointers

Roll pointers are available to prepare rods or tubing for wire drawing. As an alternative to swaging, roll pointers include a pair of rolls instead of dies, which are driven manually or by a motor. Each pointer has a pair of rolls, grooved to your specifications. The grooves will continue to get smaller, allowing the material to pass through to a desired finish size. Machinery configurations:

- Manual For fine wire or tubes

- Motorized For larger wire or tubes

Manual, A Series

Motorized, B Series

Motorized, C Series

Motorized, D/E Series

Roll Pointer Sizing

Custom rolls are available for tubing and specialty-shaped wire. Measurements are in inches.

| Machine Size | A-3 | B-3 | B-4 | C-3 | C-4 | E-1 | E-2 | D-1 | D-2 |

| Capacity-Solid | 0.1875 | 0.250 | 0.375 | 0.375 | 0.500 | 0.625 | 0.750 | 1.000 | 1.250 |

| Capacity-Tubing* | 0.1875 | 0.250 | 0.375 | 0.375 | 0.500 | 0.625 | 0.750 | 1.000 | 1.250 |

| Min. Finish Size | 0.017 | 0.031 | 0.101 | 0.046 | 0.143 | 0.120 | 0.325 | 0.312 | 0.735 |

*Outside diameter.

Max. Alloy Range Sizes

| Machine Size | A-3 | B-3 | B-4 | C-3 | C-4 | E-1 | E-2 | D-1 | D-2 |

| Low Carbon Steel | — | 0.312 | 0.312 | 0.375 | 0.500 | 0.750 | 0.750 | — | — |

| High Carbon Steel/Alloys |

— | 0.250 | 0.250 | 0.046 | 0.375 | 0.625 | 0.625 | — | — |

|

Aluminum, |

— | 0.375 | 0.375 | 0.500 | 0.500 | 0.750 | 0.750 | — | — |

| Motor Horsepower |

— | 3 | 3 | 5 | 5 | 7-1/2 | 7-1/2 | 15 | 15 |

Service, Support, Spare & In-House Made Dies!

Spooler Payoffs & Take-ups

Speeds from 10 FPM – 3,000 FPM & Spool weights from 1 pound to 10,000 pounds

Payoffs and Take-ups are for wire from a process line such as Annealing Furnaces and Coating Lines, Multi-draw machines, Bull Blocks, etc. Types of Payoffs and Take-ups include:

- Continuous Payoff and Take-up System Used for a non-stop annealing or coating process. Either Payoff or Take-up spool can be changed while the material is accumulated on the other block

- Annealing/Coating Payoff and Take-up System Used for inline paying off and taking up for an annealing or coating process

- 34 Take-up System Used following a heat treatment process where multiple wires coming through a furnace are collected. Different capstans are pulling wire through the process, and a traversing wire guide lays the wire onto different spools

Continuous Payoff & Take-up System

Annealing/Coating Payoff & Take-up System

34 Take-up System

Wire/Rod Payoffs

Up to 10,000-pound capacity

To payoff wire or rod into a process line. Types of Payoffs include:

- Overhead rod sizes up to 5/8” diameter

- Horizontal rod sizes up to 2 ½” diameter

- Payoff Turntable up to 84” diameter top plates

Horizontal Rod Payoff

Overhead Payoff with Coil Upenders

Overhead Payoff with Cage

Overhead Payoff with Turn-Table

Spoolers

For all sizes and shapes of tube and wire .001” – .750”

Additional custom size ranges are available for cable

To take up wire from a process, Spoolers can be used in conjunction with all types of machinery, such as Bull Blocks, Multi-pass machines, and Rewinders. Types of Spoolers include:

- Levelwind/Traversing Spooler A reciprocating spool is for inline spooling and is also available for specialty rewind lines. It can hold up to 6,000 pounds

- Simple Tabletop Spooler Economic Rewind for rewinding larger spools to smaller spools, from 5 to 150 pounds

- Spool Rewinder System Single unit that can payoff and take-up. Up to 10,000 pounds

Levelwind/Traversing Spooler

Economical Tabletop Spooler Rewind

Spooler Rewind System

Ancillary Wire Drawing Equipment

Ancillary options are available to add to your drawing process

- Accumulators for precise speed following between two machines

- Rotating Die Box ideal for maintaining round wire and longer die life

- Dead Block Take-up Unit ideal for nonstop operation in a drawing line

- Upenders ideal for taking a horizontal coil and making it vertical to payoff or banding

- Crimpers used primarily for mesh wire

- Packaging Turntable to convert usually unruly stands of wire coils (random fall) into high-density packages (pattern laid). For use with Dead Block machinery.

Crimper

Packaging Turntable

Rotating Die Box

Stripper Block

Upenders

Deadblock Take-up Unit

For a partial to full restoration of older MacBee machinery. This includes the replacement of certain obsolete components and controls.

Over time, applications and production requirements can change over time, and machines may no longer be useful in their original configuration. MacBee equipment owners can increase the machine’s capabilities and stay current with safety standards for a fraction of the cost of a new machine. FENN can provide an upgrade solution for your existing MacBee machinery through a Rebuild or Retrofit.

How does the rebuild process work?

FENN will have a discussion about the condition, age, wear and production goals of your machine, then an inspection of your current machine will be done. Our team will then provide you with a comprehensive evaluation which will outline customized recommendations and estimates of time, labor and materials required for the rebuild/retrofit.

Spare Parts

Ordering spare parts and accessories from the OEM guarantees that you receive the correct item and ensures that the quality and compatibility of the part will match that of the original machine.

Not sure about your exact requirements?

Rest assured, FENN’s dedicated staff will take the time to work with you, understanding your unique needs and providing the support you need to make the best decision for your MacBee equipment.