A Mini-Series: Torin’s Take on Magazine & Conveyor Springs

Magazine and Conveyor Belt Springs

In this edition of “Springs, Springs, Springs!” Torin discusses the topic of magazine and conveyor belt springs.

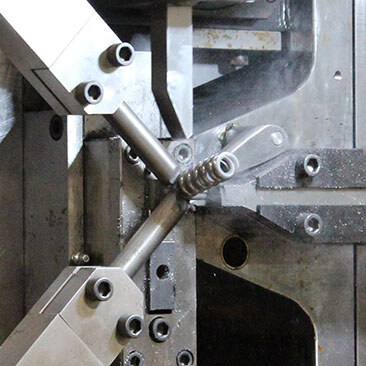

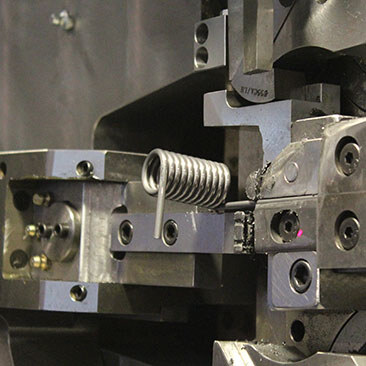

Magazine and Conveyor Belt Springs: Magazine springs, commonly thought of for their use in firearms, can also be manufactured for use in conveyor belts. Aesthetically, a conveyor spring differs from a magazine spring by the two hooks that are on the ends of the conveyor spring. Both types of springs can be made on a single point spring coiler with torsion because this configuration produces the best quality spring.

Magazine springs require tight tolerances that are difficult to maintain during production. However, Torin coilers consistently hold twist and the user-friendly software allows for quick, easily made adjustments. A Torin single point spring coiler with torsion axis holds tight tolerances on the feed assembly and coiling area, which results in the production of superior magazine springs. When being formed, it is important for magazine springs to have a specific “twist” when coming off the coiler – rather than lying flat. This “twist” is necessary because when the spring is stress relieved in an oven to harden, the heat in the oven makes the spring twist which then results in a flat magazine spring. If the spring was flat to begin with, the movement in the oven would cause it to be twisted as a final product.

FENN’s Torin FZ Series spring coilers are very repeatable, which means producing magazine springs on a Torin coiler requires very little warm-up time for the machine. The benefit is not only being able to produce quality springs without wasting time for the machine to warm-up, but also there is less waste of material. Torin’s coilers result in high-quality, tight-tolerance, and time-saving spring production.

Conveyor belt springs, also known as “belting” springs, are used in various industries for different conveyor belt applications. For example, the food industry uses these types of springs in their conveyor belts, because stainless steel can withstand both hot and cold temperatures without compromising the structural integrity of the spring. Additionally, they can be easily cleaned and sterilized. Metal conveyor belt springs are also commonly used in the packaging industry. For best performance conveyor springs must be flexible, while still holding their shape. Conveyor belts can be made using plastic and fabrics, but these materials are not as durable as metals.

There are many different types of springs, and unlimited uses for them. However, one aspect that is important across the board, is how well a spring is made. Torin spring coilers have been trusted for over 100 years to manufacture consistent, accurate, and quality springs. While there are many different types of spring making machinery, FENN is the exclusive provider of the Torin brand. With a “made in the USA” reputation, spring makers know they are producing reliable springs on quality machinery. Manufacturers know a final product is only as good as its parts, and springs are integral parts in many final products.

Variety of Magazine & Belting Springs Made on Torin Coilers