How Swaging Machines Work: What is A Swaging Machine?

A swaging machine (also known as a swager) is a piece of metal forming equipment that can point, form, or reduce wire, rod, or tube to reduce, shape, taper, bond, or form metal parts. Swaging machines essentially shape or forge the metal part through a series of very rapid blows delivered by rotating hammers and forming dies around a piece of work. One of the reasons swaging is so economical and thus attractive is that the metal is formed – not machined – so there are no wasted (and costly) material scraps.

Swagers can be made to form a material that is either hot or cold. Cold swaging is generally more popular because of its hardening effect on most materials. The swaging process also improves grain structure, giving the part greater strength and an unusually fine finish.

Types of Swaging Machines and How They Work:

There are several different types of swagers or swaging machines, and each type is ideal for specific applications:

- Stationary Swagers – These enable the production of complete parts from a round, square, or rectangle-shaped piece of metal. The stationary swager gets its name because the spindle assembly inside the swager always remains stationary while the roller cage rotates.

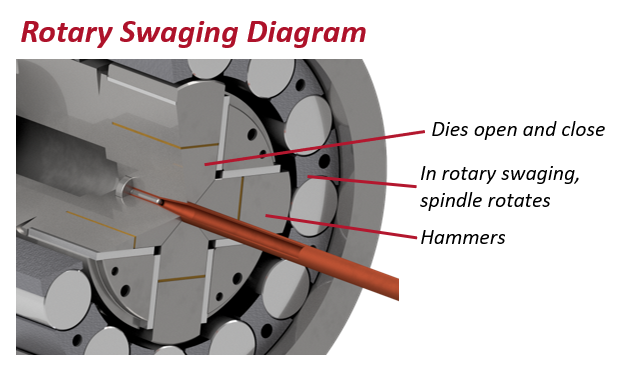

- Rotary Swagers – Available in either a 2-die or 4-die configuration, the rotary swager is only capable of swaging circular cross sections. Unlike the stationary die swager, the spindle assembly revolves around the work, thus getting its “rotary swaging” name.

- Long Die Swagers – Use the same method as the rotary swager to form parts but is preferred to create long, shallow tapers.

- Hydroformers – Hydroforming is a modification to the traditional rotary swaging technique, where wedges are used to open the dies while the spindle is rotating, so the workpiece can be inserted before and removed after swaging. Hydroformers are used for assembling parts, such as attaching a fitting to a piece of cable.

Swaging Machine Accessories

While a swaging machine can technically be used independently, manufacturers often opt for add-on attachments that help make the swaging process faster, simpler, and/or safer for the operator. Any swager OEM will likely offer a variety of swager accessories. Some examples include:

Hydraulic Table Feeders

Hydraulic table feeders utilize a hydraulically powered sliding top, a highly accurate way to feed product into the machine automatically. Because hydraulic feed systems are so accurate, they are often utilized for making parts requiring high precision, such as aerospace parts. Systems may be controlled with manual buttons or a more sophisticated HMI screen.

Sound Enclosures

Because of the inherent nature by which swagers form or forge metal parts, they create noise in the process. A swager owner who wishes to minimize that noise could consider a sound enclosure, typically consisting of a steel outer shell that encases soundproofing material.

Integrated Robotics

As manufacturing becomes increasingly automated, robotics have been integrated into processes like swaging more and more. Robotics, such as a robotic arm, can work in conjunction with the swager and other accessories, such as a hydraulic feed table. Something like an integrated robotic arm can work to quickly, safely, and effectively feed and remove the material once the process is complete. One benefit to integrated robotics is that the machine/system requires less operator interaction, meaning that one operator can operate more than one machine simultaneously, increasing productivity.

Although swaging is a relatively simplistic technology, it continues to be a preferred method for metal forming – from military to automotive, medical, and aerospace applications.