Laboratory Rolling Mills for Research & Development

Achieving perfect consistency in materials is crucial for scientists and researchers, and the secret often lies in the humble lab roller mill. This versatile equipment is a workhorse in many labs, making particle size reduction a breeze.

Whether you're new to the world of lab equipment or a seasoned veteran, understanding the role and function of lab roller mills is crucial. From their design to operation, these machines are more than meets the eye. Keep reading to investigate the intriguing area of lab roller mills and discover what makes them an indispensable tool in modern labs.

What are Lab Roller Mills?

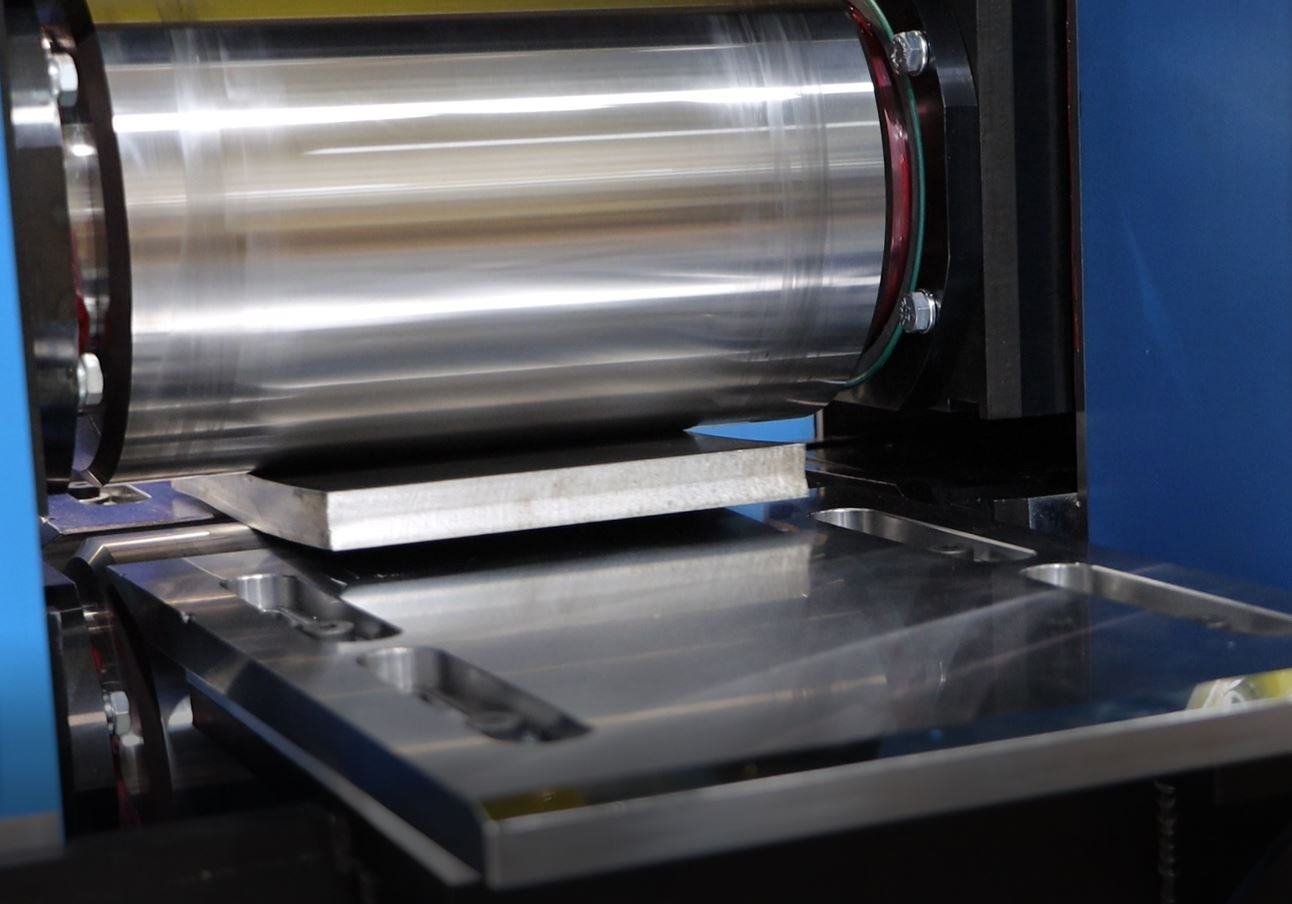

Lab roller mills, a form of rolling mill, play a central role in laboratory settings. They are invaluable tools that enable efficient particle size reduction. Their primary function is reducing research materials to achieve uniformity and consistency without creating scrap. Meticulous design and seamless operation are vital components of this machinery's effectiveness.

It’s essential to explore the mechanics of lab roller mills to understand them thoroughly. For example, their operating mechanism basically involves two functions: feeding and reducing. Your material passes through the mill and faces two cylindrical rollers. Their counter-rotating action causes the material to pass between them, reducing thickness. While laboratory rolling mills have similarities, their specific form, size, and application might vary substantially.

Knowing the ins and outs of such vital lab equipment empowers you to use it most efficiently. Stay keen, as understanding lab roller mills paves the way toward optimized laboratory procedures. Their pivotal role in today's labs spotlights their significance in scientific research, making them indispensable tools for modern laboratories.

Applications in Research & Development

In research and development, lab roller mills' capabilities extend across an array of scientific domains. Using their principal function of particle size reduction, they contribute significantly to various scientific disciplines.

Material Science

Lab roller mills are making significant strides in material science. They produce uniform particle sizes and ensure a homogenous sample, enhancing the consistency and reliability of results. For example, in ceramics and glass research, a lab roller mill provides the means to achieve optimal material consistency, aiding innovative material development.

Pharmaceuticals

In the pharmaceutical sector, precision rules overall. Lab roller mills play a definitive role in both drug design and production. Accurate sizing and uniformity brought about by these mills improve drug dissolution rates, enhancing their therapeutic efficacy. For example, in formulation research, lab roller mills enable the reduction of active pharmaceutical ingredients, aiding in developing novel drug formulations.

Metallurgy

Bridging the gap between research and robust metal production, lab roller mills present in metallurgical laboratories help forge resilient alloys. Rolling mills shape and reduce metal thickness, facilitating purity analysis and alloy properties. A laboratory rolling mill significantly aids in developing advanced, lightweight materials such as high-strength aluminum alloys, propelling the scope for aerospace research.

Polymer and Plastics

Lab roller mills occupy a central role in polymer and plastic studies. They expedite the analysis of polymer behavior under varying conditions, thereby benefiting the design and testing of new materials. For example, a lab roller mill can assist researchers in understanding the impact of fillers on the mechanical properties of composites.

Advantages of Using Lab Roller Mills

Precision and Control

Lab roller mills provide excellent precision and control. These units let you accurately regulate speed and particle size, crucial for obtaining dependable results in your experiments. This attribute of lab roller mills makes it possible for exact repeatability, a critical feature for scientific applications. For example, in pharmaceutical research, slight particle size variations can significantly affect drug dissipation rates. With these roller mills, you can fine-tune the settings, ensuring that your research materials meet the desired specifications.

Versatility

Lab roller mills are not application-specific but useful in many scientific fields. For instance, you'd find laboratory rolling mills in material science labs aiding alloy development, and they also significantly contribute to polymer behavior analysis in plastics research. They can handle a variety of materials, from hard, brittle substances to soft, flexible specimens. This versatility is attributed to their widespread use in diverse research fields.

Cost-Effectiveness

Finally, lab roller mills are cost-effective solutions in the long run. While the initial investment might seem considerable, their efficiency, precision, and versatility offer excellent value for money. They can process large volumes of materials faster than manual methods, reducing labor costs and time spent. Also, their high precision reduces the wastage of expensive research materials — a major bonus in cost-sensitive environments like research and development laboratories.

FENN's Lab Roller Mills

FENN's Lab Roller Mills are leaders in particle size reduction. Precision-engineered, they offer versatile operations catering to the varying needs of research and development laboratories. Renowned for their efficiency, these lab roller mills can handle various material types, reinforcing their versatility.

Features and Benefits

Running a Lab Roller Mill by FENN, you'll experience a machine that's systematized to perfection. A few of the inherent features amplifying its usability are:

- Customizable Roll Gap: You can adjust the roll gap, manipulating the nature of the ground product.

- Unparalleled Thickness Precision: Cherish the high-end thickness control, critical for uniform particle size.

- Variable Speed Control: Optimize the milling speed, adopting the optimum operability for each material.

- Long-lasting Durability: High-grade construction materials ensure the longevity of the lab roller mill.

These features significantly reduce labor costs, expedite material processing, and curb research material wastage, resulting in the overall cost-effectiveness of operations.

Customer Testimonials

FENN's lab roller mills have gained notable user admiration, confirmed by multiple positive testimonials. Users rave about the superior reduced precision and adjustable speed, assuring reliable results. There's also commendation for the mill's robustness and longevity, a testament to its top-quality construction. FENN's Lab Roller Mills have established trust and confidence among users, playing a pivotal role in varied scientific fields like Material Science, Pharmaceutics, Metallurgy, and Polymer/Plastics research.

Contact FENN for More Information

Lab roller mills are essential for achieving uniform particle sizes and enhancing consistency in results. FENN's Lab Roller Mills stand out for their precision engineering, versatility, and efficiency. Contact us today for more information and equip your lab with the best to enhance your research outcomes.