Different Types of Swaging Machines

Swaging Machines

Different Types of Swagers

FENN offers a variety of different types and sizes of swagers to be used for the pointing of tube, rod, and wire for redraw. Swaging machines can also be used to shape, reduce, taper, bond, or form metal parts. Unlike other methods, swaging uses a rapid succession of hammer strikes to form the metal. This chipless metal forming method is an efficient way to produce products with minimal material waste – ideal for companies working with precious metals.

Types of FENN swagers include

Stationary Swagers:

Using a stationary swager, complete parts can be made from entry rounds, squares, or rectangles. Stationary swagers can produce any cross-section other than a perfect circle and can perform both hot and cold swaging operations. During stationary die swaging the spindle assembly remain stationary and the roller cage rotates. Types of stationary swagers are simultaneous blow and alternate blow. On a simultaneous blow, a stationary swager can create fluted shapes and cross-circular sections. When utilizing an alternate blow, stationary swagers can create rectangular shapes, squares, and hexagons.

- Application examples include aerospace tube components and fluid control tubes.

Rotary Swagers:

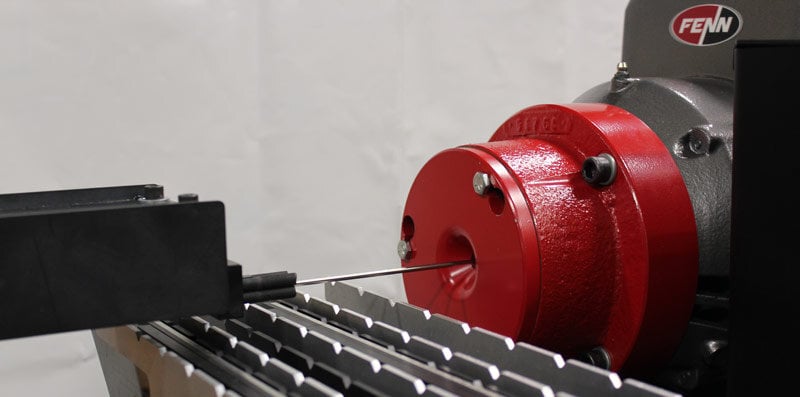

FENN rotary swaging machines are used for pointing, sizing and forming wire, rod and tube. In rotary swaging, forming dies backed by hammer blocks revolve around the work. As the spindle revolves, centrifugal force throws the hammers and dies outwards against a series of rollers surrounding the spindle. Each time the hammer blocks strike diametrically opposed rollers, they are driven inward, causing the die halves to close and compress the metal being swaged. (See diagram below) Rotary swagers can be either 2-die or 4-die configuration and the swaged section is always circular.

- Examples include cartridge heaters, hypodermic tubing, piping, armaments, and logging industry applications.

2-Die vs. 4-Die Swagers – The necessary die configuration is application specific. A 2-die rotary swaging machine is mostly commonly used on small parts and creates a better surface finish. Whereas a 4-die rotary swaging machine is commonly used for pointing and is capable of larger initial reductions on larger parts.

Hydroformers:

Hydroformers are used for assembling parts, such as fittings to cables, and for making  reductions between shoulders such as on convoluted tubing. Hydroforming is a modification of the rotary swaging principle where wedges are used to open the dies while the spindle is rotating so the work can be inserted before and removed after swaging.

reductions between shoulders such as on convoluted tubing. Hydroforming is a modification of the rotary swaging principle where wedges are used to open the dies while the spindle is rotating so the work can be inserted before and removed after swaging.

- Application examples include sailing rigging equipment, architectural cable railings, and recreational ropes course cables.

Long Die Swagers:

Long die swaging machines utilize the same principle as the rotary swaging method to  produce long, shallow tapers for items such as furniture legs, sporting goods and aerospace products – for tapering tubing up to 24” in length. Long die swagers serve a wide variety of materials, both welded and seamless tubing of either ferrous or nonferrous metals, from stainless steel to aluminum. A long die swager is only necessary with taper length exceeds the standard die length on a rotary swager.

produce long, shallow tapers for items such as furniture legs, sporting goods and aerospace products – for tapering tubing up to 24” in length. Long die swagers serve a wide variety of materials, both welded and seamless tubing of either ferrous or nonferrous metals, from stainless steel to aluminum. A long die swager is only necessary with taper length exceeds the standard die length on a rotary swager.

Every swaging machine, die, hammer and wear part are crafted in-house at FENN’s East Berlin, CT location. Our application specialists and spare parts department are available to assist you with a full range of stocked parts, ready for shipment. FENN offers additional swager components and options to optimize your swaging process. From sound enclosures, coolant/slushing systems, feeders, and completely automated turn-key systems – FENN can design and build a swaging machine for your application.