Different Types of Rolling Mills & What They Do

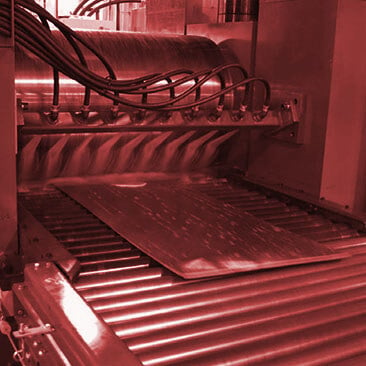

Rolling Mills

FENN offers a full range of custom rolling mills for the production of precision strip in straight lengths or coil to coil rolling. Every rolling mill machine is designed with features to maximize uptime and increase production quantities. FENN rolling mills are available for a variety of materials, and a wide range of applications, across a diverse list of industries such as aerospace, automotive, military, renewable energy, and materials research. When choosing a rolling mill machine that is suitable for your application, there are many variable factors to consider, for instance whether the mill should perform hot or cold rolling. FENN’s experienced engineers will take the time to work with you to understand your process and expectations. After collecting preliminary data and a discussing the intended application, FENN’s experts will recommend the best rolling mill machinery for your specific production requirements.

Some of the many different types of rolling mill machines that FENN offers are:

- Two-High: Generally, a 2-HI mill is used for hot or cold breakdown and finishing of bar, sheet or strip. A wide range of sizes with separating force capacities from 10,000 lbs. (4.53 MT) to over 3,000,000 lbs. (1360 MT) are available.

- Three-High: A 3-HI mill is an economic milling solution for the breakdown of rod and ingot.

- Four-High: A 4-HI mill may be used for finish rolling of thin gauge stock. 6-HI roll inserts are also available for narrow width ribbon and foil products.

- Combination: A combination rolling mill is a versatile “two-in-one” type of metal rolling mill that permits both 2-HI and 4-HI rolling operations.

- Tandem: These rolling mills are used for multiple pass rolling, combining two or more mill stands. Tandem mills are often used with turks heads, edgers, dancers, inter-stand tensiometers, payoff and take-up equipment.

- Horizontal: This type of a rolling mill is designed for the field of powered metallurgy, plastics and battery industries.

- Laboratory: FENN designs custom, specialized mills engineered to meet the critical requirements of metallurgists and scientists in research and university fields, as well as pilot line development. Learn more about FENN’s offering of Laboratory Rolling Mills

- Mill with Winders: A mill set up with winders on either side allows for the rolling of continuous coil for sheet or thin foil.

FENN Rolling Mills are available in a wide range of configurations and sizes, for an assortment of engineering, manufacturing, and research and development (R&D) applications. With customizations available, FENN Steel Rolling Mills offer flexibility and numerous benefits to companies and universities who choose this equipment for their metallurgical applications. A complete offering of material handling, processing, gauging and labor-saving accessories are available for our Rolling Mill machinery. Learn more about customized auxiliary options for FENN’s rolling mills.